DTF Printing Revolution: Releasing Creativity in Textile Layout and Production

DTF Printing Revolution: Releasing Creativity in Textile Layout and Production

Blog Article

From Idea to Creation: Releasing Creative Thinking With DTF Printing on Different Fabrics

In today's dynamic realm of textile design, the usage of Straight to Movie (DTF) printing modern technology has revolutionized the process of transferring detailed designs onto various textiles. The blend of advancement and virtuosity through DTF printing opens up doors to a realm where creative imagination knows no bounds.

Exploring the Conveniences of DTF Printing

One key benefit of DTF printing is its flexibility in terms of the materials it can be applied to. Unlike some conventional approaches that are restricted to certain material kinds, DTF printing can be used on a large array of materials, consisting of cotton, polyester, blends, and even leather.

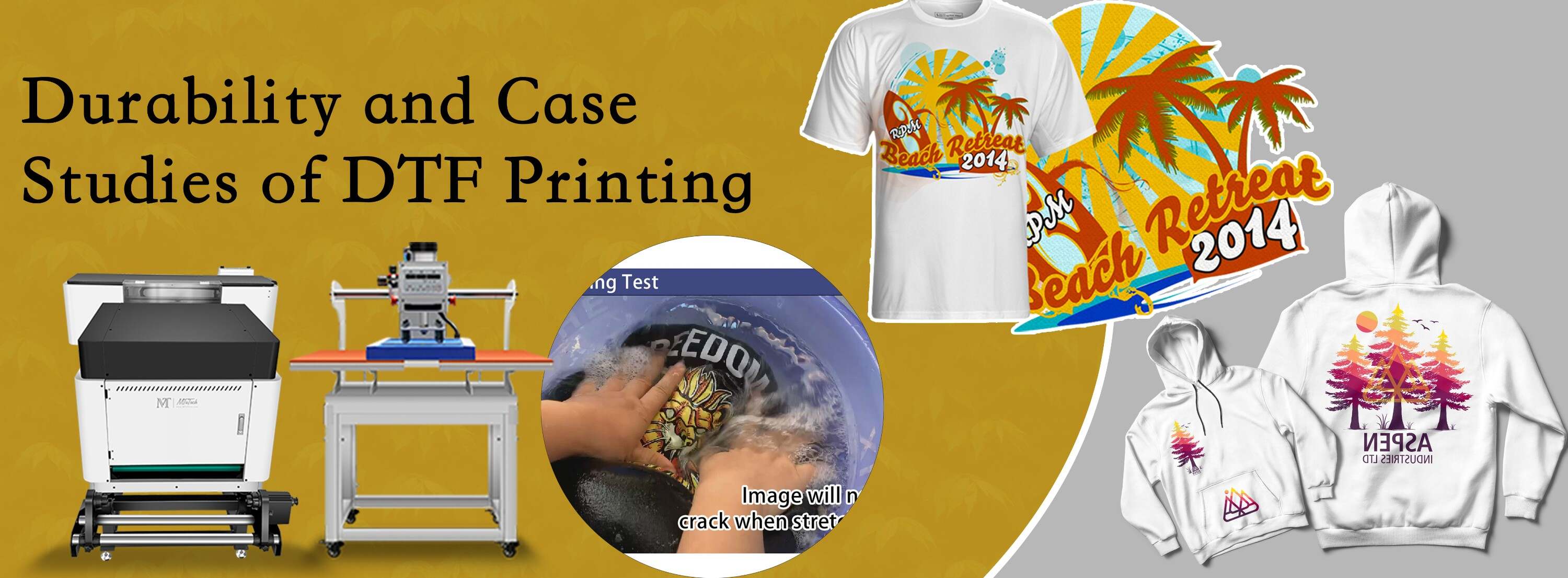

Furthermore, DTF printing uses extraordinary sturdiness, making it optimal for generating durable layouts on textiles - DTF Printing. The prints developed through DTF are understood for their dynamic colors and resistance to fading, fracturing, or peeling - making sure that the end product preserves its quality even after numerous cleans or expanded usage. This sturdiness makes DTF printing a cost-effective option for manufacturers seeking to create high-grade, long lasting styles on fabrics

Creating With DTF: Idea

Creating efficiently with DTF printing includes grasping the intricacies of digital layout software application and comprehending just how to optimize styles for the very best results on various materials. When producing designs for DTF printing, it is crucial to take into consideration the material appearance, color, and kind to ensure that the final item fulfills expectations. Here are some tricks and pointers to boost your DTF layout process:

Resolution is Key: Begin with high-resolution photos to preserve clarity and sharpness in your styles. Low-resolution pictures can result in a pixelated end product.

Color Matching: Take notice of shade accuracy when designing for DTF printing. Usage shade monitoring devices to make sure that the colors in your style translate precisely onto the material.

Vector Videos: Utilize vector graphics anywhere feasible to preserve the quality of your layouts when scaling them to different dimensions. (DTF Printing)

Examination Prints: Constantly conduct examination prints on example textiles to inspect the shades, resolution, and overall style top quality before major production.

Selecting the Right Fabrics for DTF

When taking into consideration the optimal fabrics for DTF printing, the choice of product plays a critical duty in achieving the preferred top quality and longevity of the final printed designs. Fabrics with a high polyester material are commonly preferred for DTF printing due to their capacity to hold the ink well and produce vibrant prints. By very carefully choosing the ideal fabric for DTF printing, designers can improve the long life and aesthetic effect of their styles.

Step-by-Step DTF Printing Refine

After curing, the printed style is then moved onto the fabric making use of a warmth press. The transfer process needs mindful placement to make certain that the style is applied precisely. As soon as the transfer is complete, the fabric is allowed to cool prior to the transfer movie is peeled off, leaving behind the sturdy and vivid layout on the fabric. Finally, the textile might undertake post-processing therapies to enhance the style's longevity and vibrancy, leading to a top quality end product ready for usage or display.

Showcasing DTF Masterpieces

Have you ever before admired the elaborate information and vivid colors of DTF masterpieces showcased on various fabrics? DTF printing has actually revolutionized the method designs are transferred onto fabrics, allowing for unmatched precision and richness in colors. When these DTF masterpieces are placed on display, they astound target markets with their striking visuals and meticulous craftsmanship.

One of one of the most captivating facets of showcasing DTF work of arts is the convenience it provides. Whether it's a eye-catching and bold style on a tee, a comprehensive pattern on a pillow case, or a custom print on a canvas bag, DTF printing permits unlimited opportunities. This flexibility enables designers and musicians to unleash their creativity and bring their visions to life on a large range of materials.

In addition, the longevity of DTF prints makes certain that these masterpieces can stand up to the test of time without shedding their vibrancy. Whether displayed in galleries, put read the full info here on as trendy read this garments, or utilized as decorative accents in homes, DTF masterpieces continue to excite viewers with their outstanding top quality and aesthetic allure.

Conclusion

To conclude, DTF printing supplies a versatile and innovative technique for letting loose imagination on different fabrics. By checking out the advantages of DTF printing, making with details tips and tricks, picking appropriate fabrics, and adhering to a detailed printing procedure, musicians can showcase their work of arts effortlessly. This process enables for the smooth shift from concept to development, offering endless opportunities for innovative expression.

In today's dynamic world of fabric style, the use of Straight to Film (DTF) printing modern technology has actually changed the procedure of moving complex designs onto numerous materials.Creating successfully with DTF printing involves grasping the intricacies of digital layout software application and understanding just how to optimize designs for the best outcomes on various materials.When considering the ideal textiles for DTF printing, the option of material plays a vital duty in attaining the wanted high quality and toughness of the final printed designs. The following action is printing the layout onto a special DTF transfer film using a DTF printer with the suitable ink. By discovering the benefits of DTF printing, making with particular tips and methods, choosing suitable materials, and following a detailed printing process, artists can showcase their work of arts with simplicity.

Report this page